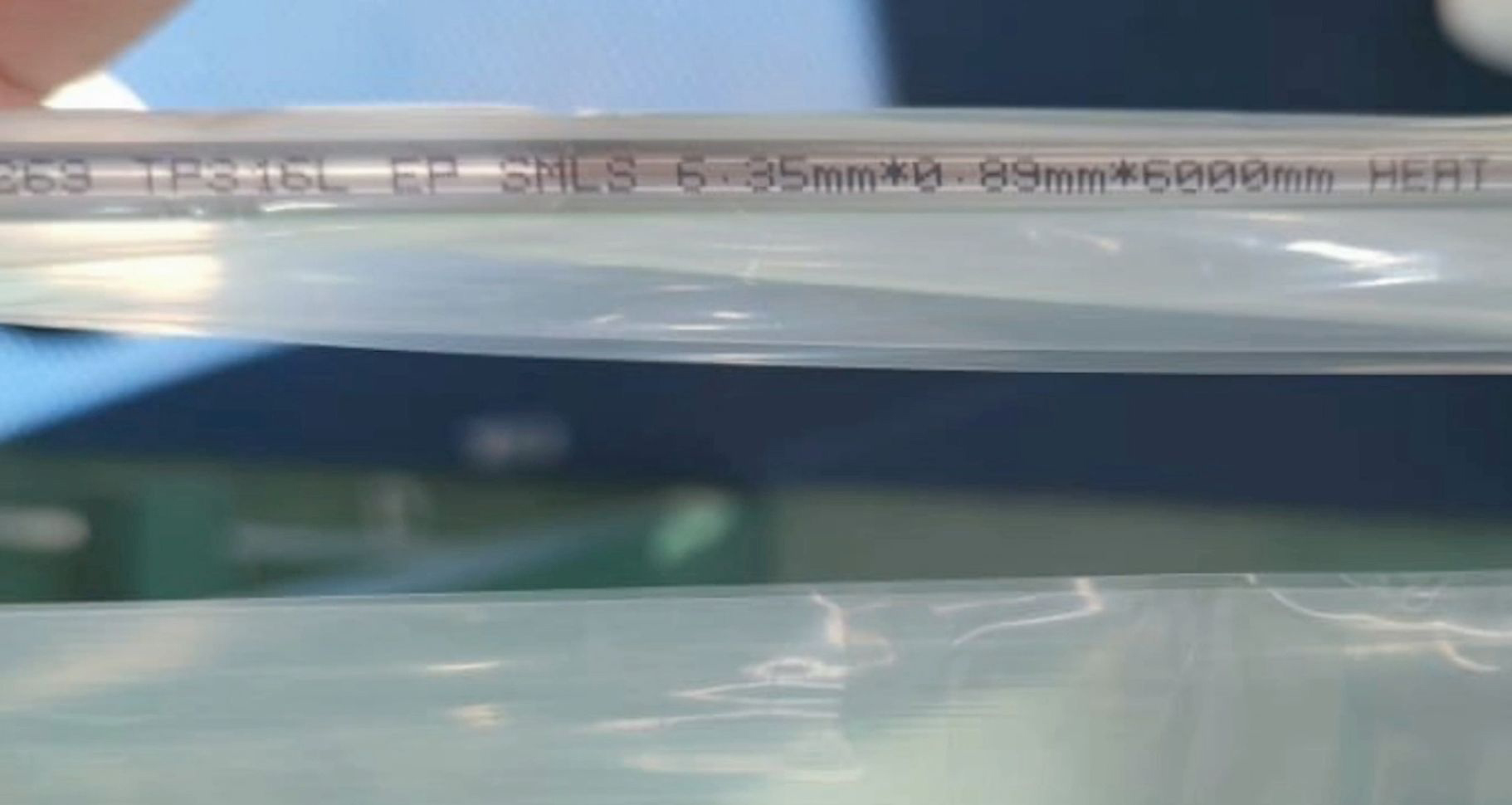

Motlakase (EP) Seamless Tube

Electropolishing ke eng?

Ho etsa motlakaseke mokhoa oa ho qetela oa electrochemical o tlosang lesela le tšesaane la thepa ho tloha karolong ea tšepe, hangata tšepe e sa hloekang kapa li-alloys tse tšoanang. Mokhoa ona o siea sebaka se benyang, se boreleli, se hloekile haholo.

E boetse e tsejoa e leho bentša ka electrochemical, ho bentša ka anodickapaho belisoa ha electrolytic, electropolishing ke ea bohlokoa ka ho khetheha bakeng sa ho bentša le ho senya likarolo tse senyehang kapa tse nang le li-geometri tse rarahaneng. Electropolishing e ntlafatsa boleng ba bokaholimo ka ho fokotsa ho ba mahoashe ho fihla ho 50%.

Electropolishing e ka nkoa e lereverse electroplating. Ho e-na le ho eketsa lesela le tšesaane la li-ion tsa tšepe tse qosoang hantle, electropolishing e sebelisa motlakase oa motlakase ho qhaqha lesela le lesesaane la li-ion tsa tšepe ka har'a tharollo ea electrolyte.

Electropolishing ea tšepe e sa hloekang ke tšebeliso e tloaelehileng ka ho fetisisa ea electropolishing. Electropolished stainless steel e na le ntlha e boreleli, e benyang, e hloekileng ka ho fetesisa e hanang ho bola. Le hoja hoo e ka bang tšepe leha e le efe e tla sebetsa, litšepe tse atisang ho etsoa ka motlakase ke 300- le 400-series stainless steel.

Ho phethoa ha electroplating ho na le litekanyetso tse fapaneng tsa ho sebelisoa lits'ebetsong tse fapaneng. Lisebelisoa tsena li hloka pheletso e mahareng. Electropolishing ke ts'ebetso e nang le bokhohla bo felletseng ba Pipe ea Ts'epe ea Motlakase e fokotsehileng. Sena se etsa hore liphaephe li nepahale haholoanyane ka litekanyo, 'me Pipe ea Ep e ka kenngoa ka nepo lits'ebetsong tse hlokolosi joalo ka lits'ebetso tsa indasteri ea meriana.

Re na le lisebelisoa tsa rona tsa ho bentša 'me re hlahisa li-tubes tsa electrolytic polishing tse fihlelang litlhoko tsa masimo a sa tšoaneng tlas'a tataiso ea sehlopha sa mahlale sa Korea.

EP Tube ea rona maemong a hloekileng a phapusi ea ISO14644-1 Sehlopha sa 5, tube e 'ngoe le e' ngoe e hloekisoa ka nitrogen ea ultra high purity (UHP) ebe e koaheloa le ho kenngoa habeli. Setifikeiti se tšoanelehang maemo a tlhahiso ea li-tubing, sebopeho sa lik'hemik'hale, mokhoa oa ho latella lintho, le ho ba mahlahahlaha ho holimo ho fanoe bakeng sa lisebelisoa tsohle.

Tlhaloso

ASTM A213 / ASTM A269

Bokhopo & Bothata

| Tekanyetso ea Tlhahiso | Bokhopo ba ka Hare | Bokhopo bo ka Ntle | Ho thatafala max |

| HRB | |||

| ASTM A269 | Ra ≤ 0,25μm | Ra ≤ 0,50μm | 90 |

Relative Elemental Composition of Tube

Tlaleho 16939(1)

Tshebetso

Qheketso (ha-tse-tsa) /to-tsa-ma-tsa-ma-tsa-na-ha-nane/ Hoa mohatsela

Kereiti ea lintho tse bonahalang

TP316/316L

Ho paka

Tube e 'ngoe le e' ngoe e hloekisitsoe ke khase ea N2, e kentsoeng ka mahlakoreng ka bobeli, e kentsoe ka har'a mekotla e habeli e hloekileng, 'me ea ho qetela ka har'a mokotla oa lepolanka.

Kamore ea EP Tube Hloekileng

Maemo a Hloekileng a Kamore: ISO14644-1 Sehlopha sa 5

Kopo

Semi-conductor/ Lipontšo/ Lijo · meriana · lisebelisoa tsa tlhahiso ea bio/ pipeline e hloekileng e hloekileng haholo/ Thepa ea ho etsa matla a letsatsi/ Lipeipi tsa enjene ea ho haha likepe / Enjene ea sefofane / Sistimi ea Hydraulic le mochini/ Lipalangoang tse hloekileng tsa khase

Setifikeiti sa Tlotlo

ISO9001/2015 Standard

ISO 45001/2018 Standard

Setifikeiti sa PED

Setifikeiti sa tlhahlobo ea TUV Hydrogen e lumellana

LBH

Stainless Steel 316L electropolished tube ke mofuta oa li-tubing tsa tšepe tse sa hloekang tse kenang kalafo e khethehileng e bitsoang electropolishing (EP). Lintlha tsa bohlokoa ke tsena:

- Boitsebiso: E entsoe ka tšepe e sa hloekang ea 316L, e nang le carbon content e tlaase ha e bapisoa le 304 tšepe e sa hloekang. Sena se e etsa hore e se ke ea bola 'me e lokele lits'ebetso moo ho nang le likotsi tsa ts'usumetso.

- Surface Finish: Electropolishing e kenyelletsa ho qoelisa tšupu ka bateng ea tharollo ea electrolyte e nang le motlakase. Ts'ebetso ena e qhibilihisa ho se phethahale ka holim'a kapa ka tlase ho bokaholimo ba tube, e leng se etsang hore e be boreleli, bo tšoanang. Sebaka se ka hare sa bokaholimo se netefalitsoe hore se na le boholo ba 10 micro-inch Ra.

- Lisebelisoa:

- Indasteri ea Meriana: E sebelisoa bakeng sa lits'ebetso tsa bohloeki bo phahameng haholo ka lebaka la bohloeki ba eona le ho hanyetsa ho bola.

- Tšebeliso ea Lik'hemik'hale: Mela ea mehlala ea ho lemoha H2S.

- Tsamaiso ea Liphaephe tsa Bohloeki: E loketse lisebelisoa tsa lijo le seno.

- Tlhahiso ea Semiconductor: Moo boreleli bo botle ba tube bo leng bohlokoa.

- Setifikeiti: Litlhaloso tse laolang bakeng sa li-tubing tse nang le motlakase ke ASTM A269, A632, le A1016. Tube e 'ngoe le e 'ngoe e hloekisoa ka naetrojene e hloekileng haholo, e kentsoeng, 'me e kenngoe habeli maemong a hloekileng a phaposi ea ISO Class 4.

Electropolished tubing e fana ka melemo e mengata:

- Corrosion Resistance: Ts'ebetso ea electropolishing e tlosa bofokoli bo holim'a metsi, e ntlafatsa ho hanyetsa ha thepa ho senya le ho pata.

- Smooth Surface Finish: Sephetho se kang seipone se hlahang se fokotsa khohlano, se nolofalletsa ho hloekisa le ho hlokomela. Sena se bohlokoa bakeng sa lits'ebetso tsa litlhare, ho lokisa lijo, le indastering ea semiconductor.

- Bohloeki bo Ntlafetseng: Li-tubes tse nang le motlakase li na le likheo tse fokolang le li-micro-roughness, tse fokotsang kotsi ea ho hōla ha baktheria. Li loketse lits'ebetsong tsa bohloeki.

- Ho Fokotsa Tšilafalo ea Khomaretsi: Sebaka se boreleli se nyahamisa likaroloana le litšila ho khomarela, ho netefatsa bohloeki ba sehlahisoa.

- Ntlafatso ea Aesthetics: Ponahalo e bentšitsoeng e khahla ebile e loketse lits'ebetso tsa maemo a holimo.

Li-tubing tse nang le motlakase li sebelisoa hangata libakeng tse mahlonoko moo bohloeki, ho thibela kutu, le libaka tse boreleli li leng bohlokoa.

| Che. | Boholo | |

| OD(mm) | Thk(mm) | |

| 1/4″ | 6.35 | 0.89 |

| 3/8″ | 9.53 | 0.89 |

| 1/2″ | 12.70 | 1.24 |

| 3/4″ | 19.05 | 1.65 |

| 3/4″ | 19.05 | 2.11 |

| 1″ | 25.40 | 1.65 |

| 1″ | 25.40 | 2.11 |

| 1-1/4″ | 31.75 | 1.65 |

| 1-1/2″ | 38.10 | 1.65 |

| 2″ | 50.80 | 1.65 |

| 10A | 17.30 | 1.20 |

| 15A | 21.70 | 1.65 |

| 20A | 27.20 | 1.65 |

| 25A | 34.00 | 1.65 |

| 32A | 42.70 | 1.65 |

| 40A | 48.60 | 1.65 |