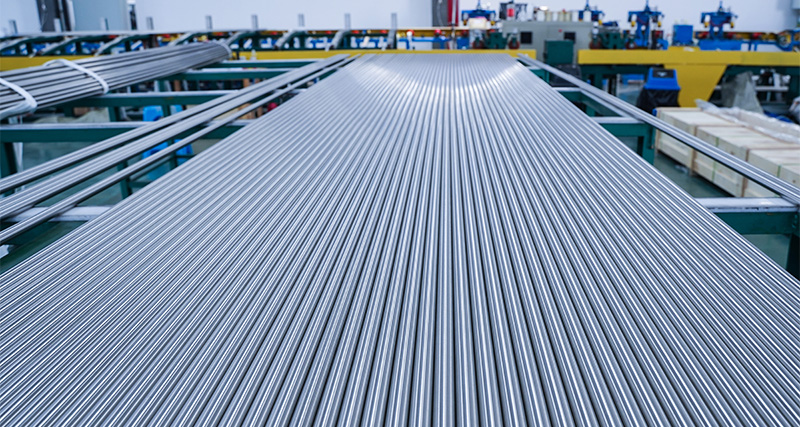

Seamless Tube e Khanyang e nang le Annealed (BA)

Tlhaloso ea Sehlahisoa

Ho annealing e khanyang ke ts'ebetso ea ho annealing e etsoang ka har'a vacuum kapa sepakapaka se laoloang se nang le likhase tse sa sebetseng (joalo ka haeterojene). Sepakapaka sena se laoloang se fokotsa ho oxidation ea bokaholimo ho isa bonyenyaneng e leng se fellang ka bokaholimo bo khanyang le lera le lesesaane haholo la oxide. Ho pickling ha ho hlokahale kamora ho annealing e khanyang kaha oxidation e nyane haholo. Kaha ha ho na ho pickling, bokaholimo bo boreleli haholo e leng se fellang ka ho hanyetsa ho betere ho mafome a likoti.

Kalafo e khanyang e boloka boreledi ba bokaholimo bo phutholohileng, 'me bokaholimo bo khanyang bo ka fumanoa ntle le ho sebetsoa ka mor'a ho sebetsoa. Kamora ho benya ho khanyang, bokaholimo ba tube ea tšepe bo boloka khanya ea pele ea tšepe, 'me bokaholimo bo khanyang bo haufi le bokaholimo ba seipone bo fumanoe. Tlas'a litlhoko tse akaretsang, bokaholimo bo ka sebelisoa ka kotloloho ntle le ho sebetsoa.

Hore ho be le ho tjhesa ho kganyang ho sebetse hantle, re hlwekisa bokahodimo ba tube mme re se na dintho tse tswang kantle pele re ho besa. Mme re boloka sepakapaka sa ho besa ha ontong se se na oksijene (haeba ho lakatseha sephetho se kganyang). Sena se finyellwa ka ho tlosa kgase e batlang e le yohle (ho etsa vacuum) kapa ka ho fallisa oksijene le naetrojene ka haeterojene e omileng kapa argon.

Ho tjheseletsa ka vacuum bright annealing ho hlahisa tube e hlwekileng haholo. Tube ena e fihlela ditlhoko tsa mela ya phepelo ya kgase e hlwekileng haholo jwalo ka boreledi ba ka hare, bohlweki, kganyetso e ntlafetseng ya mafome le phokotso ya kgase le dikarolwana tse tswang tshepeng.

Lihlahisoa tsena li sebelisoa lisebelisoa tse nepahetseng, lisebelisoa tsa bongaka, liphaephe tsa bohloeki bo phahameng ba indasteri ea semiconductor, liphaephe tsa likoloi, liphaephe tsa khase tsa laboratori, ketane ea indasteri ea lifofane le ea haedrojene (khatello e tlase, khatello e mahareng, khatello e phahameng) phaephe ea tšepe e sa hloekang ea Ultra high pressure (UHP) le masimo a mang.

Hape re na le thepa ea lipeipi tse fetang limithara tse 100,000, tse ka kopanang le bareki ka linako tse potlakileng tsa ho tlisa thepa.

Sehlopha sa Boitsebiso

| UNS | ASTM | EN |

| S30400/S30403 | 304/304L | 1.4301/1.4307 |

| S31603 | 316L | 1.4404 |

| S31635 | 316Ti | 1.4571 |

| S32100 | 321 | 1.4541 |

| S34700 | 347 | 1.4550 |

| S31008 | 310S | 1.4845 |

| N08904 | 904L | 1.4539 |

| S32750 | 1.441 | |

| S31803 | 1.4462 | |

| S32205 | 1.4462 |

Tlhaloso

ASTM A213 /ASTM A269/ASTM A789/EN10216-5 TC1 kapa ho ya ka ditlhoko.

Ho ba thata le ho ba thata

| Tekanyetso ea Tlhahiso | Ho se tsitse ha ka hare | Bokaholimo ba OD | Bongata ba ho tiea | ||

| Mofuta oa 1 | Mofuta oa 2 | Mofuta oa 3 | Mofuta | HRB | |

| ASTM A269 | Ra ≤ 0.35μm | Ra ≤ 0.6μm | Ha ho kopo | Sepolishe sa Mekaniki | 90 |

Tshebetso

Ho phutholla ka serame / Ho taka ka serame / Ho phuthela ka serame.

Ho paka

Chupu e 'ngoe le e 'ngoe e koahetsoe lipheletsong ka bobeli, e pakiloe ka mekotleng e hloekileng ea lera le le leng 'me ea ho qetela e kentsoe ka har'a lepolanka.

Kopo

Lik'hemik'hale le petrochemical/ Matla le matla/ Tlhahiso ea phapanyetsano ea mocheso/ Litsamaiso tsa hydraulic le tsa mechini/ Phetisetso ea khase e hloekileng

Setifikeiti sa Tlhompho

Tekanyetso ea ISO9001/2015

Tekanyetso ea ISO 45001/2018

Setifikeiti sa PED

Setifikeiti sa teko ea ho lumellana ha Hydrogen sa TUV

LBH

- Annealing e Felletseng.

- Ho kenngoa ha metsi ka har'a Isothermal.

- Annealing e sa fellang.

- Ho tshwarwa ha spherification.

- Ho hasanya, kapa ho kopanya ka tsela e ts'oanang.

- Ho Fokotsa Khatello ea Kelello.

- Ho tsosolosa ho kenngoa ha kristale.

Ho annealing ke mokhoa oa kalafo ea mocheso o fetolang thepa ea 'mele le ka linako tse ling le lik'hemik'hale tsa thepa ho eketsa ho se sebetse hantle le ho fokotsa ho thatafala ho etsa hore e sebetse haholoanyane. Mokhoa oa ho annealing o hloka hore thepa e be kaholimo ho mocheso oa eona oa ho nchafatsa ka nako e behiloeng pele e pholile.

Ho kenya lintho ka hare ke mokhoa oa ho phekola mocheso o sebelisetsoang ho fetola litšobotsi tsa litšepe le thepa e 'ngoe, hangata ho li etsa hore li be bonolo, li be bonolo haholoanyane, 'me li se ke tsa robeha habonolo. Ho kenyelletsa ho futhumatsa thepa ho fihlela mochesong o itseng ebe o e pholisa butle ka tsela e laoloang, ho laola sebopeho sa kristale.

| Tjhe. | Boholo (mm) | Boholo ba Tube ea EP (316L) E hlokometsoe ke ● | |

| OD | Thak | ||

| Tube ea BA Ho rarahana ha bokaholimo ba ka hare Ra0.35 | |||

| 1/4″ | 6.35 | 0.89 | ● |

| 6.35 | 1.00 | ● | |

| 3/8″ | 9.53 | 0.89 | ● |

| 9.53 | 1.00 | ||

| 1/2” | 12.70 | 0.89 | |

| 12.70 | 1.00 | ||

| 12.70 | 1.24 | ● | |

| 3/4” | 19.05 | 1.65 | ● |

| 1 | 25.40 | 1.65 | ● |

| Tube ea BA Ho rarahana ha bokaholimo ba ka hare Ra0.6 | |||

| 1/8″ | 3.175 | 0.71 | |

| 1/4″ | 6.35 | 0.89 | |

| 3/8″ | 9.53 | 0.89 | |

| 9.53 | 1.00 | ||

| 9.53 | 1.24 | ||

| 9.53 | 1.65 | ||

| 9.53 | 2.11 | ||

| 9.53 | 3.18 | ||

| 1/2″ | 12.70 | 0.89 | |

| 12.70 | 1.00 | ||

| 12.70 | 1.24 | ||

| 12.70 | 1.65 | ||

| 12.70 | 2.11 | ||

| 5/8″ | 15.88 | 1.24 | |

| 15.88 | 1.65 | ||

| 3/4″ | 19.05 | 1.24 | |

| 19.05 | 1.65 | ||

| 19.05 | 2.11 | ||

| 1″ | 25.40 | 1.24 | |

| 25.40 | 1.65 | ||

| 25.40 | 2.11 | ||

| 1-1/4″ | 31.75 | 1.65 | ● |

| 1-1/2″ | 38.10 | 1.65 | ● |

| 2″ | 50.80 | 1.65 | ● |

| 10A | 17.30 | 1.20 | ● |

| 15A | 21.70 | 1.65 | ● |

| 20A | 27.20 | 1.65 | ● |

| 25A | 34.00 | 1.65 | ● |

| 32A | 42.70 | 1.65 | ● |

| 40A | 48.60 | 1.65 | ● |

| 50A | 60.50 | 1.65 | |

| 8.00 | 1.00 | ||

| 8.00 | 1.50 | ||

| 10.00 | 1.00 | ||

| 10.00 | 1.50 | ||

| 10.00 | 2.00 | ||

| 12.00 | 1.00 | ||

| 12.00 | 1.50 | ||

| 12.00 | 2.00 | ||

| 14.00 | 1.00 | ||

| 14.00 | 1.50 | ||

| 14.00 | 2.00 | ||

| 15.00 | 1.00 | ||

| 15.00 | 1.50 | ||

| 15.00 | 2.00 | ||

| 16.00 | 1.00 | ||

| 16.00 | 1.50 | ||

| 16.00 | 2.00 | ||

| 18.00 | 1.00 | ||

| 18.00 | 1.50 | ||

| 18.00 | 2.00 | ||

| 19.00 | 1.50 | ||

| 19.00 | 2.00 | ||

| 20.00 | 1.50 | ||

| 20.00 | 2.00 | ||

| 22.00 | 1.50 | ||

| 22.00 | 2.00 | ||

| 25.00 | 2.00 | ||

| 28.00 | 1.50 | ||

| Tube ea BA, Ha ho kopo mabapi le ho rarahana ha bokaholimo ba ka hare | |||

| 1/4″ | 6.35 | 0.89 | |

| 6.35 | 1.24 | ||

| 6.35 | 1.65 | ||

| 3/8″ | 9.53 | 0.89 | |

| 9.53 | 1.24 | ||

| 9.53 | 1.65 | ||

| 9.53 | 2.11 | ||

| 1/2″ | 12.70 | 0.89 | |

| 12.70 | 1.24 | ||

| 12.70 | 1.65 | ||

| 12.70 | 2.11 | ||

| 6.00 | 1.00 | ||

| 8.00 | 1.00 | ||

| 10.00 | 1.00 | ||

| 12.00 | 1.00 | ||

| 12.00 | 1.50 | ||